Quality Assurance

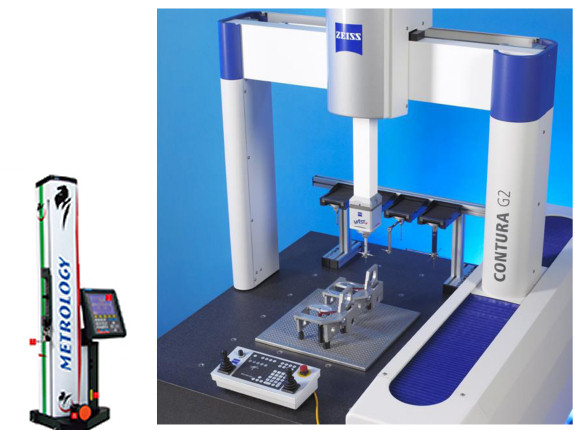

We have in house CMM to inspect dimensional features which require a CMM for inspection.

We also have all the basic measuring equipments that are required to measure the parts.

We procure and maintain thread plug gauges, plug gauges, pin gauges and all other types of gauges as per the requirement of quality plan for a particular component.

We maintain 2 separate sets of measuring equipments – one for the Quality department and another for the machine shop.

During machining, every component is inspected as per the “Stage-Inspection plan” provided by the Quality department to the shop.

After completion of the machining operation, during FAI, 100% inspection of the part is carried out and during production, 100% inspection of all critical dimensions is carried out.

Our CMM Specification as below:

ZEISS – Contura G2 RDS With Vast XXT Probe System

Other Outsourced Activities:

- Heat treatment

- Anodizing

- Passivation

- Conversion coating

- Painting

- Plating

The above activities are outsourced only to OEM approved suppliers.